In the realm of fleet management, the utilization of software tailored for preventive maintenance is paramount. This technology-driven approach not only streamlines operations but also ensures optimal vehicle performance and longevity. Dive into the world of Fleet Management Software for Preventive Maintenance as we explore its significance and benefits.

Introduction to Fleet Management Software for Preventive Maintenance

Fleet management software is a specialized tool designed to help businesses manage their fleet of vehicles efficiently. One key aspect of this software is preventive maintenance, which involves scheduling regular maintenance tasks to prevent breakdowns and ensure the longevity of the vehicles.Preventive maintenance is crucial in fleet management as it helps reduce unexpected downtime, lower repair costs, and improve overall safety.

By staying ahead of potential issues, fleet managers can keep their vehicles in optimal condition, ultimately increasing productivity and customer satisfaction.

Role of Technology in Enhancing Preventive Maintenance Processes

Technology plays a significant role in enhancing preventive maintenance processes in fleet management. With the help of advanced software solutions, fleet managers can automate maintenance schedules, track vehicle performance in real-time, and receive alerts for upcoming maintenance tasks.Additionally, technology enables the collection of valuable data on vehicle usage, performance, and maintenance history.

This data can be analyzed to identify patterns, predict potential issues, and optimize maintenance schedules for maximum efficiency. Overall, technology empowers fleet managers to make data-driven decisions and proactively address maintenance needs, ultimately improving the reliability and longevity of their fleet.

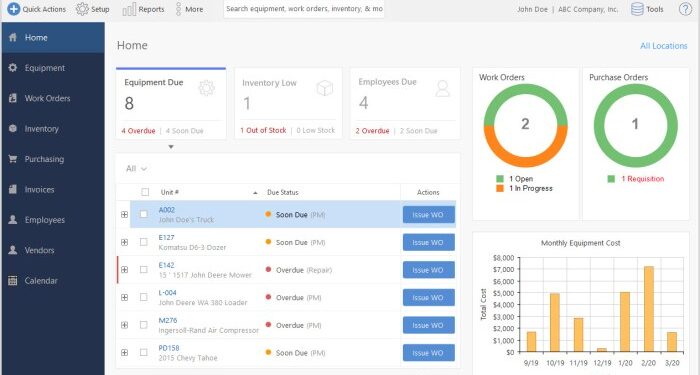

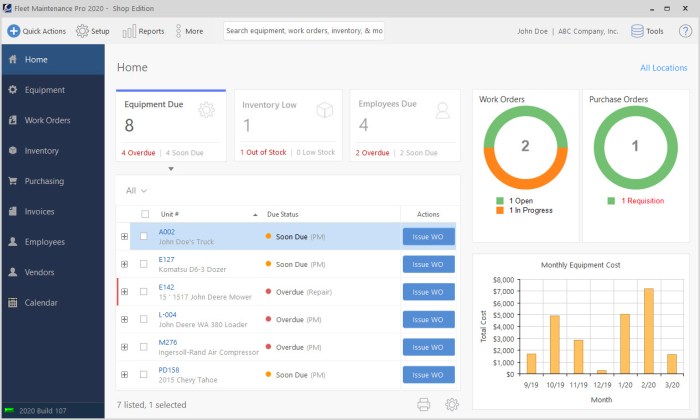

Key Features of Fleet Management Software for Preventive Maintenance

Effective preventive maintenance is crucial for keeping a fleet of vehicles running smoothly and minimizing downtime. Here are some key features that a fleet management software should have to facilitate preventive maintenance:

1. Automated Maintenance Scheduling

One essential feature is the ability to schedule regular maintenance tasks automatically based on factors like mileage, engine hours, or time intervals. This ensures that preventive maintenance is carried out on time without manual intervention.

2. Inventory Management

A good fleet management software should include inventory management features to keep track of spare parts and supplies. This helps in ensuring that the necessary parts are available for maintenance tasks, reducing downtime.

3. Work Order Management

Work order management capabilities allow users to create, assign, and track maintenance tasks efficiently. This feature streamlines the process of preventive maintenance by providing a centralized platform for managing work orders.

4. Real-Time Monitoring and Alerts

Real-time monitoring of vehicle health and performance metrics, along with alerts for potential issues, play a crucial role in preventive maintenance. By receiving instant notifications about maintenance needs, fleet managers can address problems before they escalate.

5. Reporting and Analytics

Comprehensive reporting and analytics tools help fleet managers track maintenance activities, analyze trends, and identify areas for improvement. This data-driven approach enhances the effectiveness of preventive maintenance strategies.

Implementation of Fleet Management Software for Preventive Maintenance

Implementing fleet management software for preventive maintenance involves several steps to ensure seamless integration and effective utilization of the software within an organization.

Steps Involved in Implementing Fleet Management Software for Preventive Maintenance

- Assessment of Current Maintenance Processes: The first step is to evaluate the existing maintenance procedures to identify areas that can be improved with the implementation of the software.

- Selection of the Right Software: Choosing the appropriate fleet management software that aligns with the organization's needs and requirements is crucial for successful implementation.

- Data Migration: Transferring existing maintenance data to the new software system in a structured and organized manner is essential to maintain continuity in maintenance operations.

- Customization and Configuration: Tailoring the software to suit the specific preventive maintenance tasks and workflows of the organization ensures maximum efficiency and effectiveness.

- Training and Onboarding: Providing comprehensive training to staff members on how to use the software effectively for preventive maintenance tasks is essential for successful implementation.

- Testing and Integration: Conducting thorough testing of the software and integrating it with existing systems to ensure smooth functionality and seamless operation.

- Ongoing Support and Maintenance: Continuous support and maintenance of the software, along with regular updates and upgrades, are necessary to keep the system running smoothly and efficiently.

Data Collection and Utilization within the Software for Preventive Maintenance Tasks

Data is collected within the fleet management software through various sources such as vehicle sensors, maintenance logs, and historical maintenance records. This data is then utilized to generate preventive maintenance schedules, identify potential issues before they escalate, track maintenance costs, and optimize maintenance workflows for improved efficiency and cost-effectiveness.

Training Required for Staff to Use the Software Effectively for Preventive Maintenance

- Basic Software Training: Staff members need to be trained on the basic functionalities of the software, including how to input data, generate reports, and schedule preventive maintenance tasks.

- Advanced Feature Training: Training on advanced features such as data analysis, predictive maintenance capabilities, and integration with other systems is essential for staff members to leverage the full potential of the software.

- Regular Refresher Training: Continuous training sessions and refresher courses should be provided to ensure that staff members stay updated on the latest software updates and features for effective preventive maintenance management.

Benefits of using Fleet Management Software for Preventive Maintenance

Fleet management software for preventive maintenance offers numerous benefits over traditional methods. These advantages include cost savings, improved efficiency, and proactive maintenance planning through predictive analytics.

Cost Savings

- Reduction in unexpected breakdowns and repairs, leading to lower maintenance costs.

- Optimized maintenance schedules result in longer vehicle lifespan and reduced replacement expenses.

- Minimized downtime means increased productivity and revenue generation for the fleet.

Improved Efficiency

- Automated tracking of maintenance tasks and schedules streamlines operations and reduces manual errors.

- Centralized data storage enables easy access to vehicle history, maintenance records, and performance reports.

- Real-time monitoring of vehicle health and diagnostics allows for quick decision-making and timely interventions.

Proactive Maintenance Planning with Predictive Analytics

- Utilizing historical data and predictive algorithms helps in predicting potential issues before they occur.

- Forecasting maintenance needs based on data analysis enables proactive planning and resource allocation.

- Preventive maintenance alerts and notifications ensure timely servicing, reducing the risk of major breakdowns.

Summary

As we conclude our journey through the realm of Fleet Management Software for Preventive Maintenance, it becomes evident that embracing technology in fleet operations is key to success. From enhanced data utilization to predictive analytics, the future of preventive maintenance looks promising with the aid of innovative software solutions.

FAQ Guide

How does fleet management software aid in preventive maintenance?

Fleet management software helps in scheduling regular maintenance tasks, tracking vehicle performance, and generating alerts for potential issues, thus preventing costly breakdowns.

What are the key features to look for in fleet management software for preventive maintenance?

Essential features include real-time monitoring, maintenance scheduling, asset tracking, fuel management, and integration with diagnostic tools.

How can predictive analytics within the software benefit proactive maintenance planning?

Predictive analytics can analyze historical data to predict potential maintenance needs, allowing fleet managers to proactively address issues before they escalate.